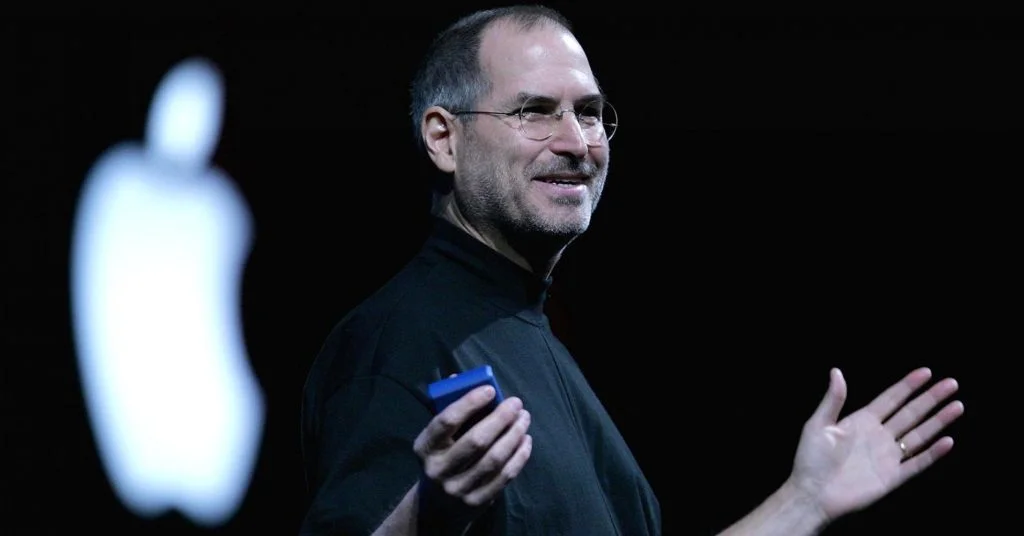

Steve Jobs once quoted: “Design is not just what it looks like and feels like. Design is how it works.”

Yes, we all would like to work in an aesthetically pleasing environment but let’s face it, warehousing space is not always the most attractive of settings, yet what really matters, is how space works for operational efficiency and the well-being of its inhabitants. Simplification of design, manufacturing, layout, processes and procedures are key to workspace improvements. Our Director, Charlie Jeary, has provided a selection of advice to consider for maximising your warehouse space.

When it comes to designing the internal layout of your warehouse space, Charlie explained there is a number of influencing factors which all need careful consideration and can affect the direction the design will take: “Firstly, you need to identify what the client wants to store, how do they want to store it, how will the materials be handled; will it be a materials handling operation, a pick and pack operation or a combination of the two?”

If we take, for example, a pallet storage operation, the main factors to consider in this instance is the type and weight of pallet and the type of forklift truck required to move the load. “Narrowing the aisle will obviously maximise the storage capacity within a building, but ensuring the correct equipment can pass easily down the aisles will have a big impact on just how narrow these aisles can be.”

At the design stage, Spaceway always works with its clients to ensure every cubic inch of space is utilised correctly and advises what is best to use within that space.

Charlie does add a note of caution… “machines designed to fit in the smallest of spaces do come with high price tags. Understanding the client’s budget for machinery at the outset is paramount, it will determine several elements of the floor layout. Equally, if the money being spent on vehicles is limited, the client could decide to go for wider passages and narrow the aisles, moving the racking and changing vehicles, at a later date.”

For a picking and packing operation, there are various considerations to be taken into account: “Establishing the products and the location of these products is often a good starting point. Questions raised from there on in are; How are the goods going to be picked and taken from the picking point to the point of dispatch? Will automation be installed? What type of racking will be used? What size aisles are required for people to work in?”

If you have a tall enough building then a multi-tier system would be ideal, the consideration in this instance is how will the products be transported between the floors – would you require conveyers or lifts? If your building doesn’t have the height required for a multi-tier system, Charlie recommends using the best racking layout to suit the products and picking operation. “Aisle width is always the biggest space contender in this scenario; do you need trollies to fit along the walkways, do they need to pass each other, which route around the floor will they take?”

“The design element at this stage is really down to basic logistics and being practical. It’s simple really, fast moving products need to be located close to the packers and slower moving items should be situated further away.”

The health and safety of the warehouse operators is also a top priority at the design stage, Charlie explained how Spaceway carefully plan the ideal picking heights when designing the layout of racking and shelving. “Guidelines are very stringent around the heights and weights of what can and can’t be lifted, and quite rightly so. The wellbeing of all employees has to be at the forefront of your mind at all times.”

If you’d like to know more about space planning and design for your warehouse, look out for Charlie’s article which is due to be featured on Warehousing Logistics International later this month.